PLCs e HMIs Programming

A MCK Automação has well trained technicians and engineers with great knowledge in PLCs and HMIs programming, developing, configuration, installation and start- up and our company also uses the most modern programming tools. We develop softwares and applications to all models available in the market all over the world.

- PLC Programming (Logical Programmable Control).

- HMI Programming (Human Machine Interaction).

- PLC Safety Programming.

More: To read more click HERE.

Supervisory System Programming

- Presentation screens, processes, control and alarms elaboration

- Synoptic screens and trend charts elaboration

- Definition and deployment of drive and control commands

- Integration with controller’s database

More To read more click HERE.

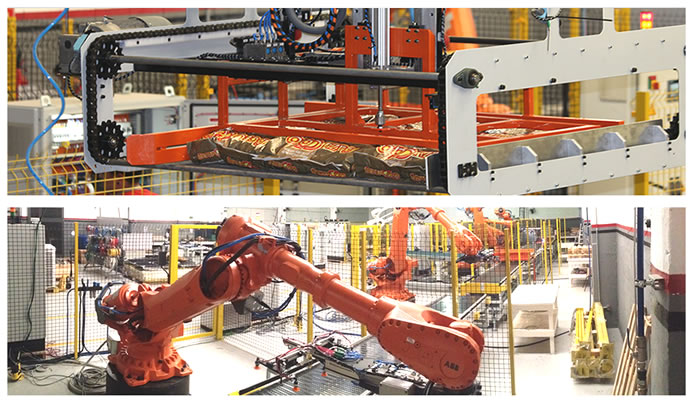

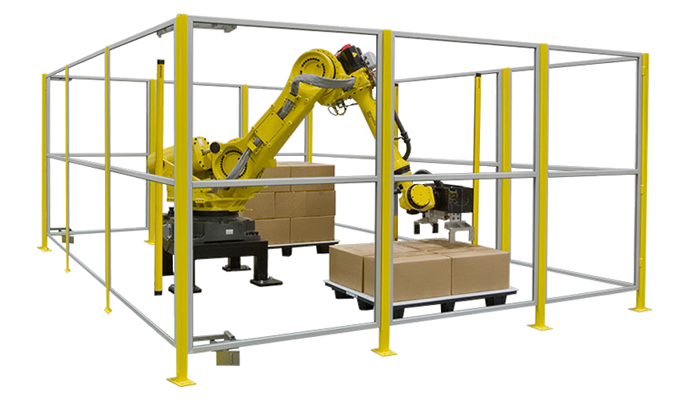

Robot Programming

MCK Automação has a trained team with great knowledge of robots’ programming and integration, robotic applications and solutions studies in general, with the main brands in the world market to guarantee greater productivity on your company’s production line, working in the following areas:

- Off-line Programming

- Support and Consulting

- Technical support

- Simulation

More: To read more Click HERE.

Electric, Pneumatic and Hydraulic Panels Setting-up

MCK has panels distributed in several industries and companies in the Brazilian market, and it’s reference in the setting up and maintenance area in this country. It has huge infrastructure and a great professional skilled team, guaranteeing MCK is capable of answering all areas with quality, agility and accuracy.

More: To read more Click HERE.

Reform and Retrofitting

MCK Automação Industrial, committed to its mission of providing your company with innovative solutions, has the Unity of Business Reform and Retrofitting. Aware of the economic crisis our country faces, MCK offers solutions of technological update of machines and industrial equipment in general, a financial attractive alternative for your business.

Our service includes:

- Complete equipment dismantling

- Painting removal

- Bearings changing

- Damaged parts machine

- Worn out or damaged parts changing

- Chemical treatment of the parts

- Belts changing

- Setting-up and start-up

- Electrical installation changing

- Electric panel and other boards reform

- PLC and HMI Installation

- Modifications in devices which show chronical problems

- New devices development

- Pneumatic installation reform

- Engines and redactors maintenance

- Start-up and client support

More: To Read More Click HERE.

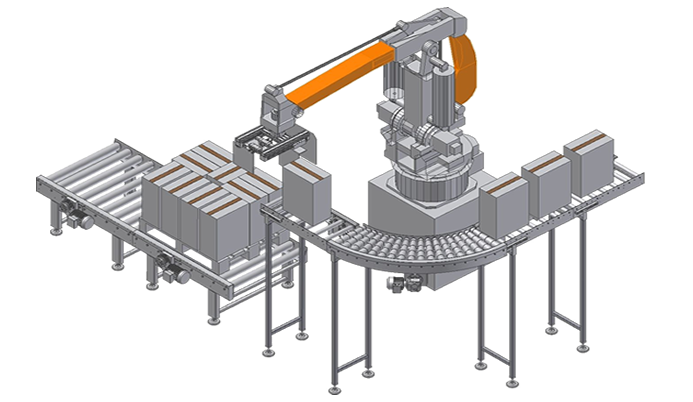

Movement System

Acquire a movement system demands the consideration of some important points which determine if that system can operate efficiently, following the safety rules and important processes for an appropriate operation.

Fundamental points:

- Facilitated maintenance

- Flexibility and ergonomics

- Reliability e safety

- Availability

- Agility

More: Click for Read More HERE.