Manipulation with Robots

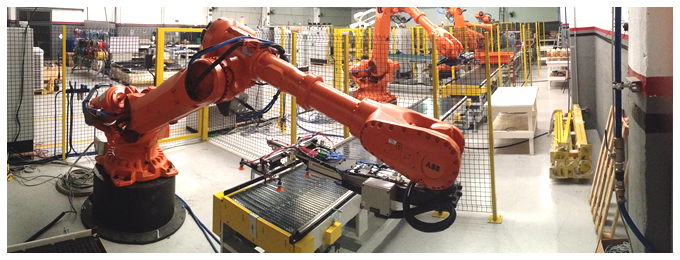

As an integrating company of the most renowned brands in the Industrial Robotics market, MCK designs and develops robotic cells for many applications. Handling systems for parts, bottles, bales, cartons, cartridges, boxing systems, automated filling machines, palletizing, positioning, etc..

In addition, our projects are part of all equipment that compose the system, such as tables and conveyors, pre-trainers of layer, indexes of products, complete security system, special claws and unique to each case, programming of PLC's, HMI's, Sequential Cells, full automation of the production line and technical assistance 24 hours a day.

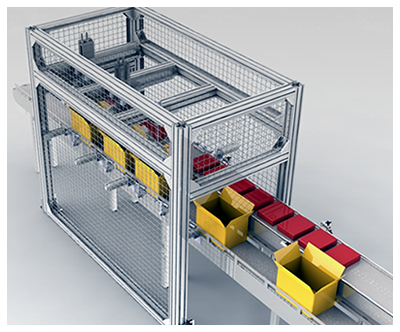

Packing (Robotized Boxing)

Robotized Packing System

The system of "boxing" robotized, the system Packing provides much more agility and precision in its final production line, automatically packing or boxing, all types of volumes, increasing its productivity, accelerating the productive processes, avoiding failures and canceling The risks of operational errors.

We develop Packing Systems projects according to the needs of each industry.

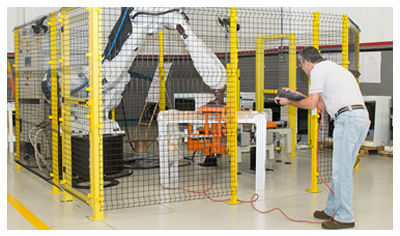

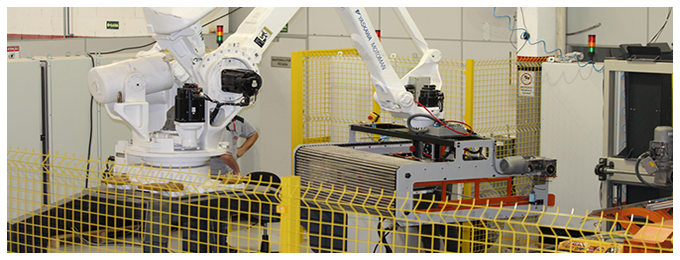

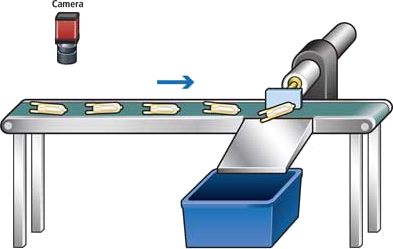

Picking

Robotic Picking System

System used for separation and selection of products, objects and volumes in general.

System used to separate the products, objects and volumes’ selection. We project and integrate the cell to provide a greater performance in the manipulation of objects, according to the chosen specifications, guaranteeing high speed, movements variability, and also high accuracy and smooth movements, not to damage fragile volumes (like food, for example).

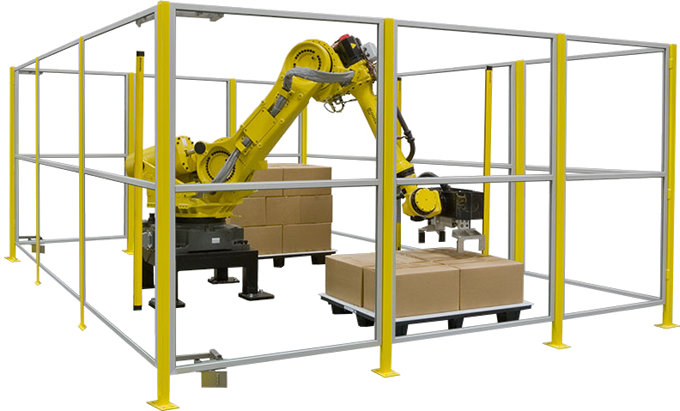

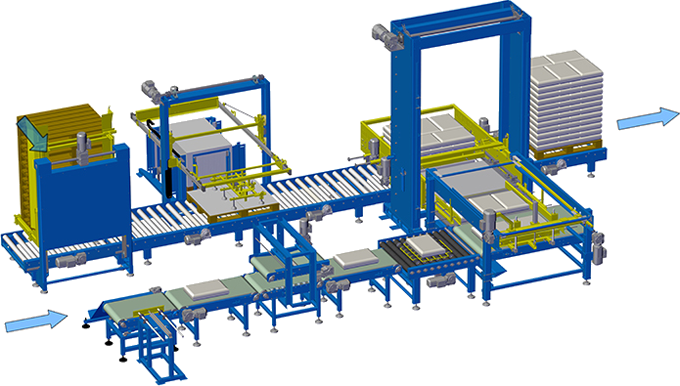

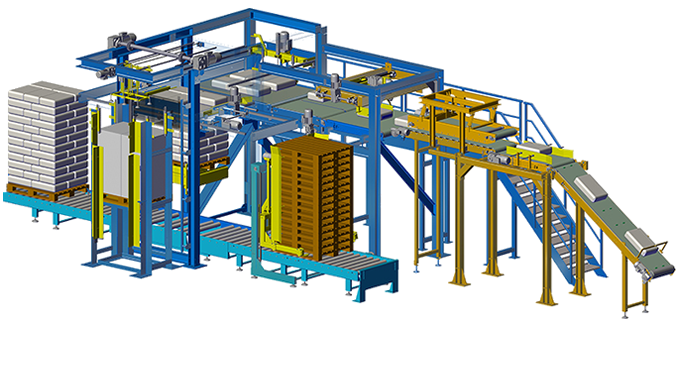

Palletizing Cells

Robotic palletizing cells are ideal to palletize any kind of volume, through a whole system, being the industrial robot the main equipment, which palletizes at thin production lines boxes, bottles, bags, bales, among others, heavy or light, with agility, continuity, safety and incomparable efficiency.

Depalletization Cells

Following practically the same train of thought of Palletization Cell, the depalletization is ideal for initial production lines, making possible the unload of newcomer volumes from other areas or even from other companies, inserting them again in some production line for new processes to be executed, guaranteeing the safety and immunity of the company.

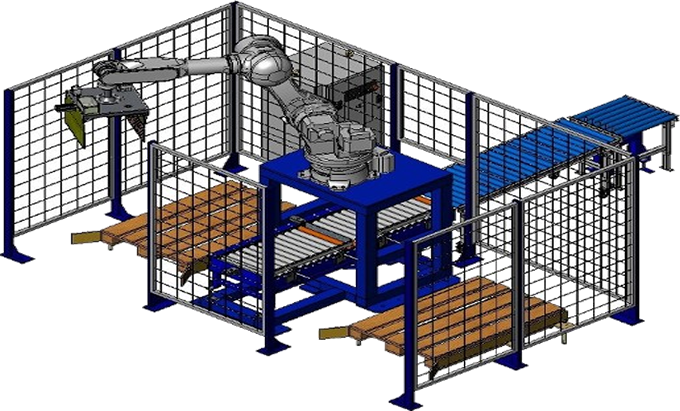

CPalletization Compact Cells

It’s a simpler option, indicated to smaller manufacturing units, because they take a reduction space. They are projected and integrated to work compacted, always keeping a high level of yield and a constant speed in its production.

Electro mechanic Palletizers

Important palletizing mechanisms, the Electro Mechanic Palletizers are fundamental and fit in the most distinct applications, mechanically palletizing bags, boxes, bales, among others, with quality.

We from MCK, We develop and execute all the integration projects of these equipments, always providing the maximum of productivity and consequently the satisfaction of our customers.

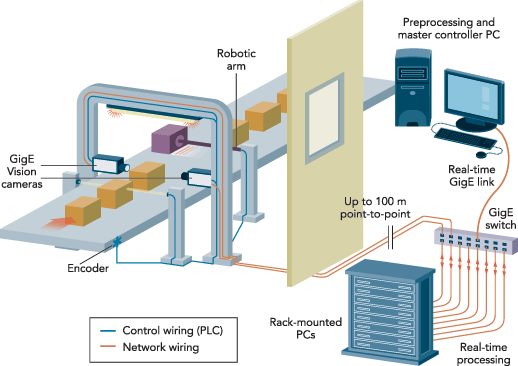

Vision System

MCK develops and integrates solutions with vision systems, making it automatic and accurate a service that operationally presents many failures, bringing full control and reliability at the product inspection, through a vision system that controls and guarantees the maximum quality of everything produced, bringing many benefits to the production:

- Waste Elimination

- Productivity Increasing

- Recalls Prevention

- Company Image Preservation

- Verification of presence and absence of components in the setting-up line.

- Bottles Inspection (presence and absence of components, leveling verification, impurities, etc.)

- Labels Inspection (printing failures, centralization and label change

- Verification of packaging and components inserted in kits

- Among others

Loads Automatic Separation

That’s what separates and directs the loads that have been brought by the tables and conveyor treadmills, it is ideal to volume separation, which are already boxed or packed, being targeted, getting the correct destination, with no need of human intervention in this process.

Products like Boxes, Bags, Bales, Packages, are some examples of possible products with automatic separation.

Conveyors

Industrial Conveyors with several forms of constructive paths, adaptable to the most distinct types of volumes and projected to innumerous types of application. MCK provides this kind of equipment, individually or integrated to a complete movement system.

Special Claws

Because of a big variety of the industry needs MCK projects and develps the robotic claws, personalized, according to each application, always keeping the excellence in adaptations.

Auto key Automation

From the smallest to the biggest, auto key is present in production lines of several industrial métiers and we have all the preparation of our professionals to automatize them, in an efficient and safe form, according to the hygiene and care rules with this kind of equipment.

- Autoclave Load and Unload

- Time and Temperature Control

- Manipulation

- Rotatory Tables

- Among Others

Bring your Project to MCK Automação.

Special Devices

Together with our Robotic Cells projects, we integrate special devices, optimizing the production processes. Pallets magazines, conveyor cars, rotatory tables, among others.

We develop standardized projects according to each need; besides that, we offer all the equipment that is part of the system: Product Conveyor, Layers Preformer, Products Indexer, Safety System, Claws, Transference and Rotatory Table, Programming, Automation and technical assistance..

Integration

We project systems and integrate them with fundamental equipment for your company’s production, making everything more practical, fast and efficient.

We develop projects that adequate to these and many other machines, for our applications to be stronger, always guaranteeing the maximum of productivity..

Movement Technology with AGV’s solution

AGV (Automatic Guided Vehicle) are vehicles conceived to move products inside a establishment, turning different machines on inside the storage area, permitting saving time, energy and space of business logistics.

The difference is the fact that they are autoguided vehicles, so they move with autonomy, automatically and with no need of an operator or fixed trails or paths in the pavement, guaranteeing a high level of flexibility for eventual development in future applications.

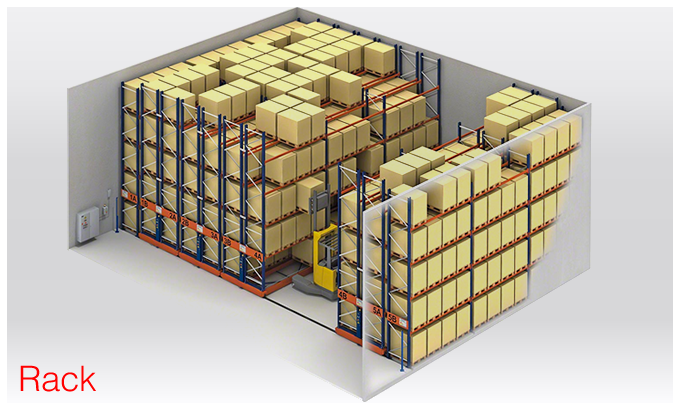

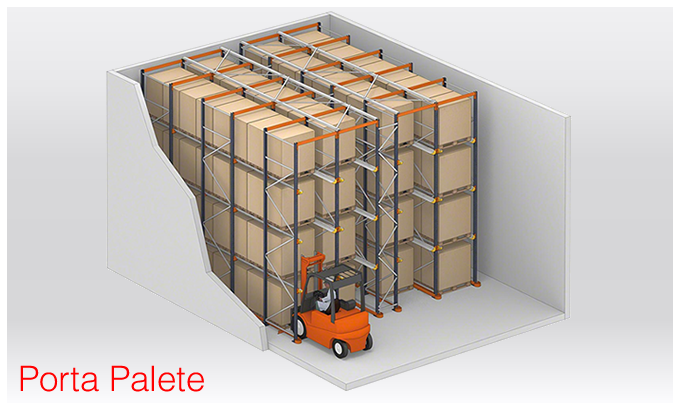

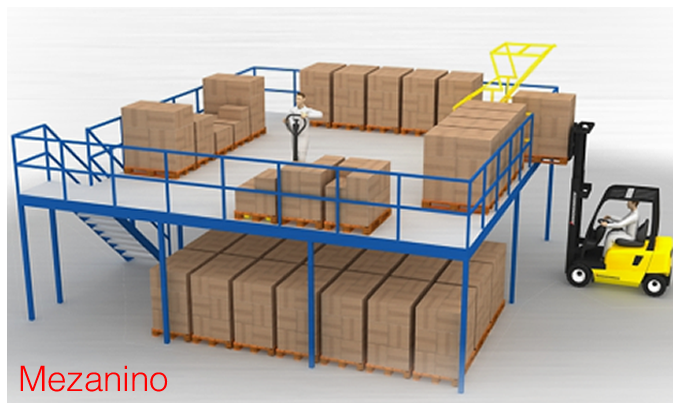

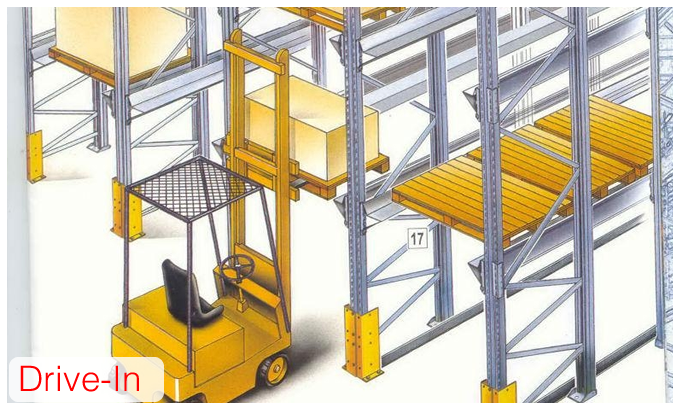

Logistics and Storing Structure

We’ve got the most modern logistics automation and storing structures, with high quality equipment, well trained professionals and partners of many years.

We also offer:

Standardized Products

- Robots parts (Claws, Pedestals, Devices)

- Feeders (Magazines, Conveyors, Racks)

- Safety Equipment (Enclosure, Safety Keys, Light Curtains, Scanners, Etc.)

Did not find what you were looking for? Contact our technical team using the form below, and detail your needs to find the best solution for your company.

Other services

Learn about other services that MCK Automação can help your company with.

Assembly of Panels

MCK has panels in several industries and companies in the Brazilian market ...

Read MoreRobot Programming

MCK has a trained team with extensive knowledge in robot programming ...

Read More