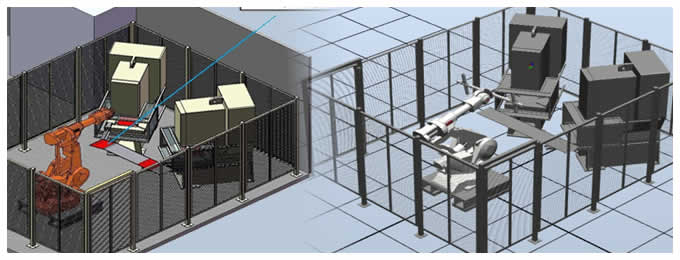

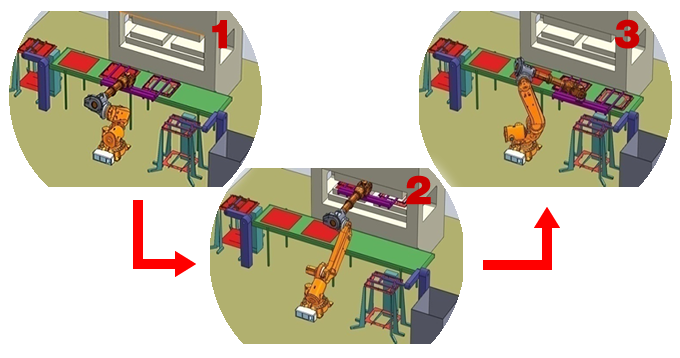

Systems “Stand Alone”

- They are systems of a basic configuration, in which the robot performs the load and unload of a press.

- Indicated for processes with average volumes of production.

- Easy and agile installment and programming

- Operator replacement, providing quality, productivity, safety, avoiding health problems to the employees and consequently reducing labor lawsuits.

Presses Feeding -> Load and Unload (“Stand Alone”)

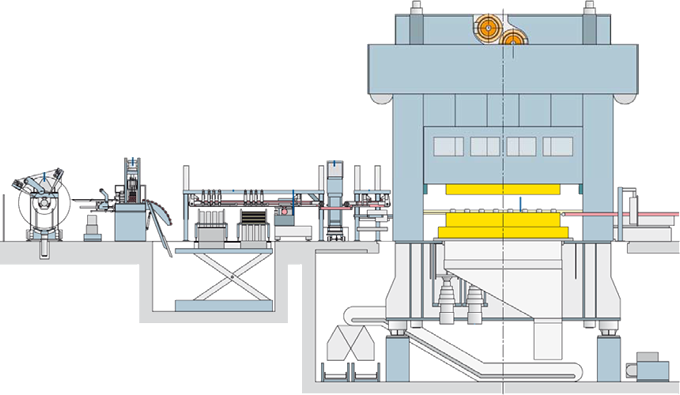

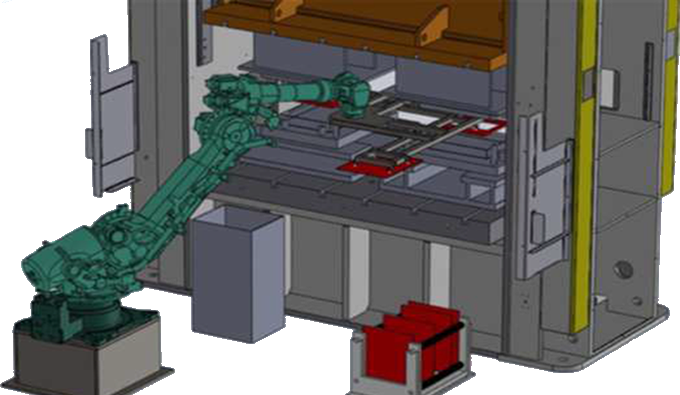

Transfer Presses – “Intra-Press”

The transfer presses were developed to respond to the compounds’ manufacture in a completely automated form with no need of labor use. The installment’s heart is built by the transfer and the element that moves the pieces from a station to the following one to perform successive necessary operations for the conformation of the piece.

MCK capacity of projecting conventional mechanical presses, hydraulic presses and serve presses with a transfer, guarantees the highest yield and productivity occupying a minimum space and assuring a better access to the most distinct installments compounds.

- They are transference systems of the product through many stages of stamping, inside the press.

- Indicated for processes with high production levels and many successive conforming and/or stamping operations.

- It substitutes with advantages the traditional stamping progressive systems: lower cost and better flexibility.

- Operator replacement, providing quality , productivity, safety and definitely avoiding accidents and health problems caused by the working environment, reducing the risk of labor lawsuits.

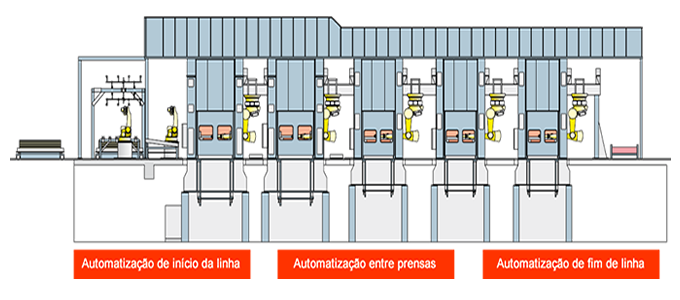

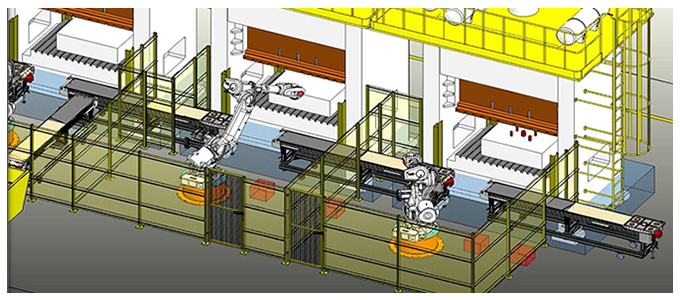

Tandem Systems – “Inter-Press”

A “Tandem” presses line is composed by a simple presses distribution, according to a line and separated by a common distance. In a line of “Tandem” presses, there is a press and a respective individual tool for each step of the piece’s manufacturing process. As it is conformed, it’s moved from a press to the following one, until the end of the line.

MCK capacity to project conventional mechanical presses, hydraulic presses and serve presses as a transfer, guarantees the highest yield and productivity, occupying a minimum space and assuring a better access to several installment’s compounds.

- It substitutes with advantage the traditional transfer by longitudinal bars system: lower cost and better flexibility

- It substitutes the operator, providing better quality, productivity, safety and avoiding occupational diseases, eliminating once and for all labor lawsuits caused by working accidents.

Safety Rules Adequacy (NR12, PPRPS, NBR13930)

It’s the adequacy that defines the requests and the safety technical decisions which must be applied by the responsible for the project, guaranteeing the physical safety and integrity of the operators and the machinery and also of the people who can be exposed to the damage.

Reform, Retrofitting and Presses Modernization

MCK is specialist in retrofitting, reform and maintenance of machines of the most distinct types and sizes, such as lathes, milling machines and in special presses.

- Equipment total disassembly

- Painting removal

- Change of all rollers

- Damaged pieces machine

- Worn out or damaged pieces change

- Chemical treatment to pieces

- Belts change

- Setting-up and start-up

- Change of all the electrical installment

- Electrical panel and other command boards reform

- PLC and HMI installment

- Modification of devices which show chronical problems

- New devices development

- Pneumatic Installment Reform

- Engines and reducers’ maintenance

- Start-up and clients’ follow up

- Among others

Did not find what you were looking for? Contact our technical team using the form below, and detail your needs to find the best solution for your company.

Other services

Learn about other services that MCK Automação can help your company with.

Assembly of Panels

MCK has panels in several industries and companies in the Brazilian market ...

Read MoreRobot Programming

MCK has a trained team with extensive knowledge in robot programming ...

Read More