Arch Welding MIG/MAG (Metal Inert Gas – Metal Active Gas)

With the crescent development of robotic and digital technology in the last years, the welding processes MIG/MAG have been advancing more and more. The results are seen in the lighter welding sources, faster remotes and improvements of the ignition process. Even though the individual configuration of robotic MIG/MAG process, currently there are almost no more technical limits because of the application variety and the optical and metallurgical quality, together with the industrial robotic. It is an excellent low-alloy iron, stainless still, aluminum and other metals welding process.

- Low cost Production

- The welding can be executed in many positions

- Wire welding with good completion

- Easy integration and operation with robots

- Others

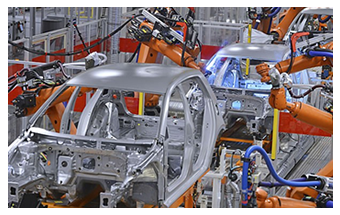

Resistance Spot Welding

Slightly connected to the automotive industry, in the in the resistance spot welding, the overlapped pieces to be welded and pressured one against the other, through electrodes moved by strengths, such as: mechanical, pneumatic, hydraulic and a mix of them.

This process brings some advantages, like:

Welding Cell through robotic Laser

The economy of the laser power guarantees reduced investment costs. The inclusion of new areas of application and optimized yield increases productivity Synergistic effects increase the efficiency of the process. So he welding through Robotic laser proves once more that the enlargement of new thermal processes of union in economy subjects wire quality, and the process safety..

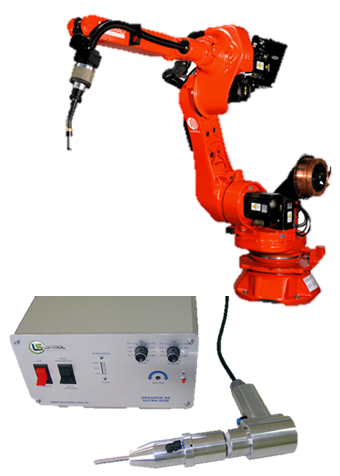

Welding Cell through Robotic Ultra-sounding

Ideal to put together non-irony metals, the welding process through ultra-sounding presents some advantages in relation to other procedures. Besides the need of a short period of welding time, no heat is produced to be dissipated, no consumable is used and the welding is more consistent, showing stronger links compared to other kinds of welding.

Main advantages:

- Process executed in the average of 1,0 second

- Cooling/ drying low time

- The welded parts do not show burrs

- It permits the use of food products labels.

- No pre-treatments are required

- High reliability of processing because of the applied ultrasonic energy uniformity

- It permits the processing of pieces with flammable products or explosives with no explosion risk.

- Among others

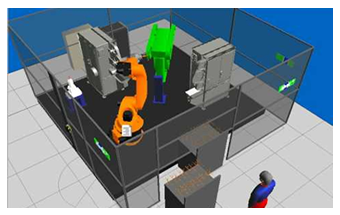

Compact Cells of Robotic Welding

Created to be operated and transported as easily as possible, the compact cells receive this name, because they occupy a compact space, keeping the agility and efficiency. Because it is compact, it has a big rotatory table and high accuracy and speed.

With only one loading and unloading area, it makes the operation easy and optimizes physical space at the factory.

- Process Quality

- Operational Costs reduction

- Production Flexibility

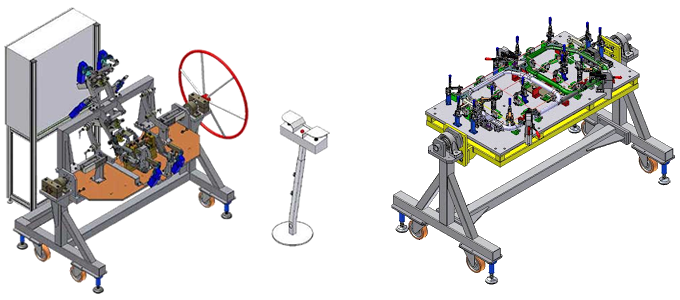

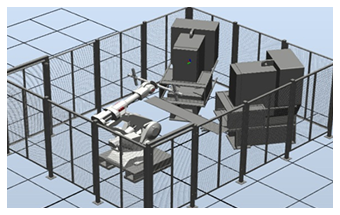

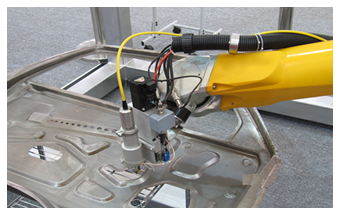

Board-Machine Welding Devices

Welding devices for the positioning and fixation of several mechanical groups, permitting a great reduction in the time of production with a relevant improvement in the quality of welded groups.

These devices can be used every day in all kinds of welding (MIG/MAG, Spot resistance, Laser, Ultrasound, among others.) They are totally adaptable and ideal for robot integration.

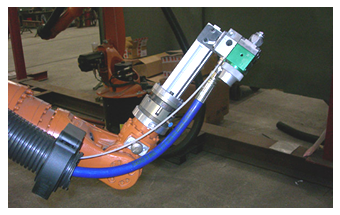

Robotic Hemming System

Executed by an industrial robot, making the application to get a greater accuracy. We develop robotic hemming systems, for the work to be performed by one cell, attending all the demands and needs of each application, strictly obeying the quality standards of MCK.

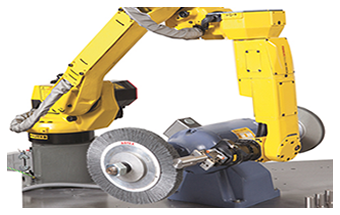

Robotic Deburring and Polishment

This cell model is ideal for the pieces’ completion process, because, besides being a delicate and risky service, industrial robots are better prepared and accurate to perform services like that. They are programmed to perform services of polishment and deburring, making this process much more accurate and efficient.

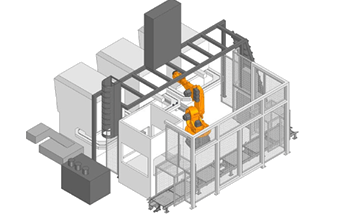

Machines Loading and Unloading

Loading and unloading of the most distinct and important machines in the industry, making the work of this fundamental equipment more practical and automatic.

Manipulative Robots

We integrate robotic cells for the products handling to be more automatic, in the product pass-through from one line to another, or in the transference, or simply in the movement inside the cell itself.

Setting-up line

We develop robotic setting-up line projects, integrating several machines and robots to the same line, making everything to work together, optimizing time and resources and guaranteeing maximum productivity.

Robotic Painting Cells

We develop strategies to paint several kinds of pieces. All painting processes are taken into consideration by MCK, according to each need, operating from projects and processes implantations, to the physical implantation of robotic cells.

Stamp Applications

Used a lot in industrial gluings, we offer integrations of complete robotic systems for the application of hotmelt, cold stamps, PUR based stamps, sealants and resin in general used in industrial production line of the mechanical metal industry.

Applicator systems of sealants coupled with robotic systems, with continuous production and without interruptions, even with high consume applications.

It is also used a lot in structural gluing, acoustic isolation system and setting-up in general, the integrations we project and execute have and offer high technology and accuracy at the applications, guaranteeing the practicality and the high productivity.

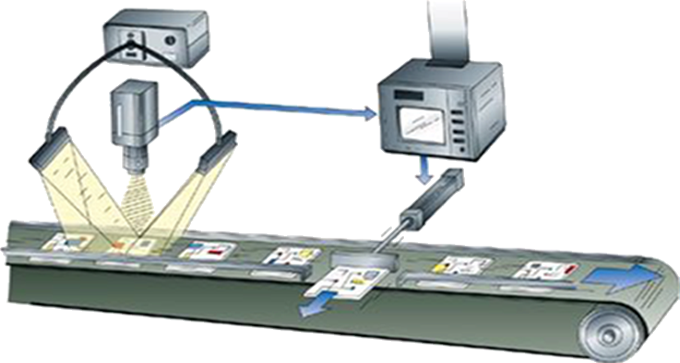

Inspection Systems

The performed inspections are based, most of times, in the analysis of visual characteristics of the product through industrial systems of vision, technology that MCK has the most experience in Brazil. In situations like dimensional analysis that require great accuracy, measuring devices are applied to laser measure devices, or digital probes can also be used.

Besides, we only work with the best providers of the most distinct measure and control equipment for mechanical, electricals and thermal measures, among others.

Cut cells and water jet

MCK is capable of uniting and integrating with perfection the systems of cut and water jet, with robotic cells, which guarantees a much bigger flexibility in the applications, together with perfection and accurate cut, with an infinity of movements of an industrial robot.

Excellent to metal cuts, compounds, stones and ceramics, food, glass, paper, among others. This type of cut is extremely accurate and has some advantages because it permits working with stacked materials, it doesn’t show any part thermally affected, it doesn’t damage the environment and many other benefits.

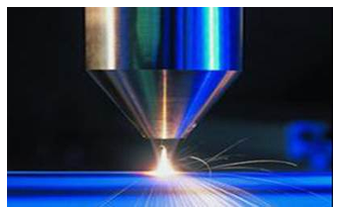

Laser Cut Cells

With the increasing development of this technology, the laser cut has been pretty applied on the most important areas of national and international metal-mechanical industry.

Knowing how to put together the efficiency and perfection of laser cut with the infinite possibilities of an industrial robot, reaching for increasing the productivity, apeed and material saving.

We project and integrate cell systems of personalized cells, according to each production’s needs. Its main applications are carbon still, inox still, acrylic, aluminum, wood, titaniun, coper, brass, among many other types of materials.

Plasma Cut Cells

As main differentials, it’s important to spot the cut speed which is faster than the oxicut, the adaptation and the efficient cut to several metal alloys, such as the aluminum or still and the cut perfection. The part which was submitted to the cut is completely perfect with an irreproachable completion (clean cut, with no traces of the funded metal).

Did not find what you were looking for? Contact our technical team using the form below, and detail your needs to find the best solution for your company.

Other services

Learn about other services that MCK Automação can help your company with.

Assembly of Panels

MCK has panels in several industries and companies in the Brazilian market ...

Read MoreRobot Programming

MCK has a trained team with extensive knowledge in robot programming ...

Read More