Supervisory System Programming

- Presentation screens, processes, control and alarms elaboration

- Synoptic screens and trend charts elaboration

- Definition and deployment of drive and control commands

- Integration with controller’s database

For the following software:

- ProficyIfix - Ge Fanuc

- ProficyCimplicity HMI - Ge Fanuc

- SimaticWinCC – Siemens

- FactoryLink – Siemens

- RsView 32 – Rockwell Automation

- RsView SE e RSView ME – Rockwell Automation

- Elipse Scada – Elipse

- Elipse E3 – Elipse /li>

- Intouch – Wonderware

- Indusoft – Indusoft

MCK also works with system projects MES (Manufacturing Execution System), PIMS (Plant Information Management System) and Web Portal.

MES (Manufacturing Execution System)

MES (Manufacturing Execution System) main role is to manage the information flow of production and centralizes them in only one system. Effectively, it is capable of reporting the right information at the right time and right place, transforming processing data into precious information.

MES are between the production planning performed in the ERP’s and the process control (supervisory systems, CLPs and PIMS), aiming the support to the strategic intentions directly or indirectly related to the manufacture operations.

- Elaboration of synoptic screens and trend charts

- Definition and implantation of navigation among screens

PIMS (Plant Information Management System)

They are data acquisition systems capable of visualize not only real time data, but also historic of processes, eliminating the information islands and concentrating information about all the areas of a project in only one data base. This base works with characteristics superior to a conventional data base, with great capacity of data base compaction and high speed at the answer to its historical base consult.

This way, it is possible to store a great volume of information with minimal resources comparing to conventional solutions. Its implementation is extremely necessary to the ones who need intelligent management systems, bringing great benefits to the professionals and to the business itself.

Portal Web Systems

A portal is a management centralized environment, responsible for the integration of areas, departments, brands and interoperability among the systems. The information is spread among the organizational levels, always at the right time and right place. With them, it’s possible to enjoy all the benefits of the RTPM concept (Real-time Performance Management).

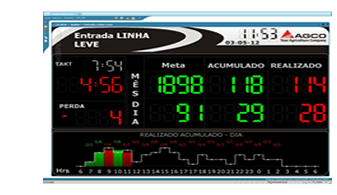

Andon Systems and Visual Signalization

In order to provide MCK clients with the total control of production, MCK performs electrical projects, projects’ specification and development of machine, panels, safety and solution that use the Andon system projects. Consult our sale department and/or our applications to more details and solutions that best fit your company’s needs.

Tower Andons

Tower Andons with drive systems by mouthpieces that may or may not be integrated to supervisory systems.

WI-FI Andons

Tower Andons with drive systems by WI-FI mouthpieces that may or may not be integrated to supervisory systems.

Led Panel Andons

Led Panel Andons with drive systems by wireless mouthpieces that may or may not be integrated to supervisory systems.

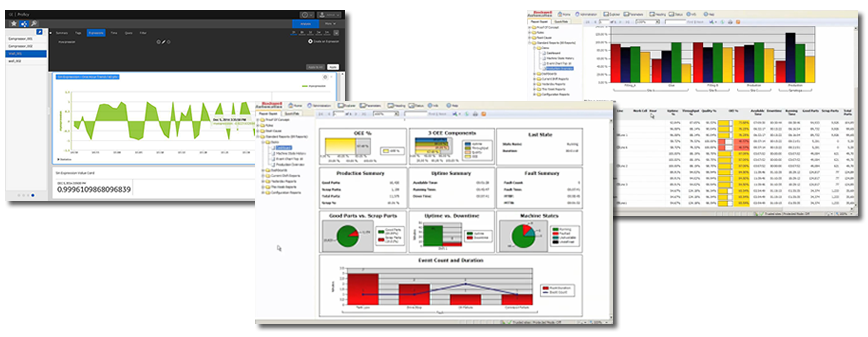

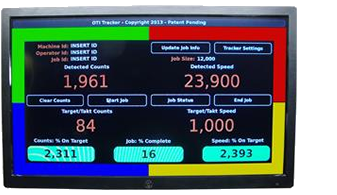

Production Report

MCK develops systems to information of factory-basis integration in order to provide de client the complete control of production. The solution is customized to the clients’ process and its goal is to analyze and integrate the generated factory-basis information with the office. This way, it is possible to obtain the following benefits:

- Implementation of automatic production reports based in the equipment work. Detailed reports of failure and reasons for it.

- Detailed notes of failures and reasons for stops.

- Traceability of production by step of the process through a code reader machine which feed the system, clearing the production order immediately.

- Analysis, project and sensors implementation in the equipment to monitor work duration, work speed, production volume, consumption and use of input, production by shift, break-break, etc.

- Possibility of sending information to the office via net cable or Wireless.

- Generation of production reports All information can be stored in PCs desktops or WEB with availability of online data on the internet. The information can also be transmitted via net to mobile devices such as handhelds, PDAs or tablets.

- Integration of the production information and process with management system.

- Automatic OEE calculus (Overall Equipment Effectiveness)- learn more about how the indicator is calculated.

- Gain in development and reliability, performing the union of the best supervisory system with production management resources in one only system.

Did not find what you were looking for? Contact our technical team using the form below, and detail your needs to find the best solution for your company.

Other services

Learn about other services that MCK Automação can help your company with.

Assembly of Panels

MCK has panels in several industries and companies in the Brazilian market ...

Read MoreRobot Programming

MCK has a trained team with extensive knowledge in robot programming ...

Read More