Projects and Consulting

MCK engineering team is expert at the conduction of projects and industrial automation consulting. With differentiated methodology and meticulous project scope, we guarantee intelligent solutions fitting the best cost-benefit to your company.

We have the best professionals in the market and we always work updating our knowledge to bring new technologies and the best ideas and information of the area, following a high-level excellence standard in results.

MCK has many solutions in projects and consulting at industrial automation with great experience recognized all around, it offers a huge line of services:

MCK Projects:

- Electrical and Electronic Projects Developing

- Pneumatic and Hydraulic Projects Developing

- Projects to controllable Programmers (CLP)

- Projects to Industrial Networks

- Supervisory Systems Programming Projects (MES, PIMS, WEB, ANDON AND VIRTUAL SIGNALIZATION)

- Robots Programming

- Electronic Boards Projects

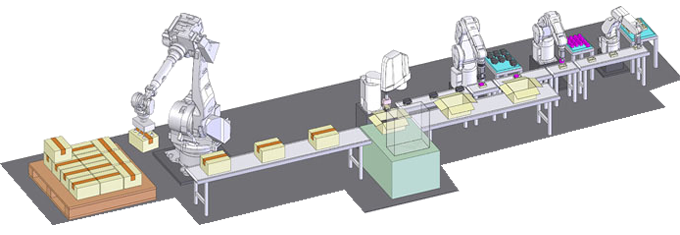

- Robotic Cells

- Machines and other Automation projects

MCK Consulting:

Setting-up Line

For a setting-up line to be considered efficient, it’s necessary, firstly, to build a strategic project with intelligent solutions based in the concept of material movement process, production turn and store reduction.

Based on this idea, MCK comes up with complete solutions for hand and automatic working stations, it is reference in the market because of its experience at the most distinct industrial areas and has a management body which coordinates and supervise all the integration process to guarantee the safety and quality of the offered service.

MCK Quality:

The quality of MCK setting-up lines may be feasible through analysis:

- Processes

- Layout Projects

- Processes Simulation

- Flow Management

- Installment Systems

- High qualified and skilled team to develop efficient processes

MCK Solutions:

As systems, integrative, MCK offers the best tools and devices to the construction of your project and its application:

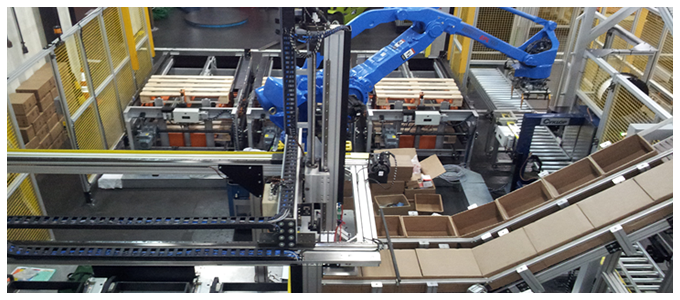

- Pick and place, manipulators, palletizers and depalletizers

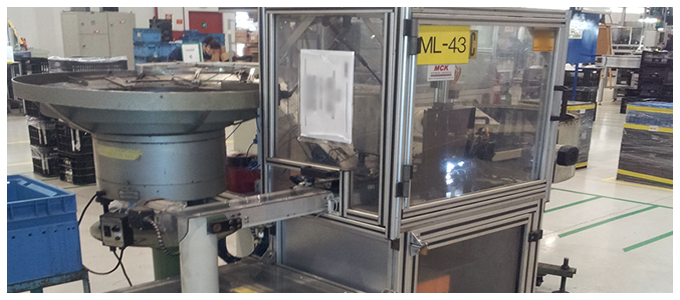

- Automatic Feeders

- Transportation System

- Wrappers

- Weighing

- Data Collectors

- Stamp Application

- CControl by Inspection- Vision Systems, Laser, Digital Touch Probes

- Benches and work stations

- Pressing, welding and brazing

- Screwdrivers, riveters and crimping machines

- Cleaning and Drying

- Inkjet Printing, laser and micropump

- Functional tests - Electrical, magnetic, watertightness

- Labeling Machines and tagging machines

- Others

MCK Differentials:

To create intelligent solutions and work stations implementation with quality, MCK takes into consideration essential factors in the execution of our processes:

Movement System

Acquire a movement system requires the consideration of some fundamental points which determine if that system may or may not operate efficiently following the safety rules and the fundamental processes for an appropriate operation.

Fundamental points:

- Facilitated Maintenance

- Flexibility and ergonomics

- Reliability and Safety

- Availability

- Agility

MCK Handling Systems:

All these concepts are integrated factor according to MCK view for the construction of movement systems with innovative solutions. Our clients receive the best projects in the market, com differentials at productive and distributive systems.

The quick technological evolution makes our team of professionals and experts to keep daily updated in new processes, tools, systems, equipment to guarantee a variety of flows and also efficient projects to our clients.

The MCK experience brings Precision, Flexibility, New Deatures and the guarantee of an Efficient Process for your products.

Kinds of Conveyors:

- Thread Feeders

- Car of Transfer

- Lifts

- Pushers

- Industrial Conveyors

- Conveyors

- Turntable

- Lifting Table

- Waiting Table

- Dump Systems

- Modular Conveyor Systems

- Screen Conveyors

- Conveyors by gravity

- Pallet Carrier

- Roller Conveyor

- Skid Conveyors

- Conveyors for Automation Systems

- Conveyors for Drive Systems

- Conveyors for Palletizing Systems

- Others

Special Machines

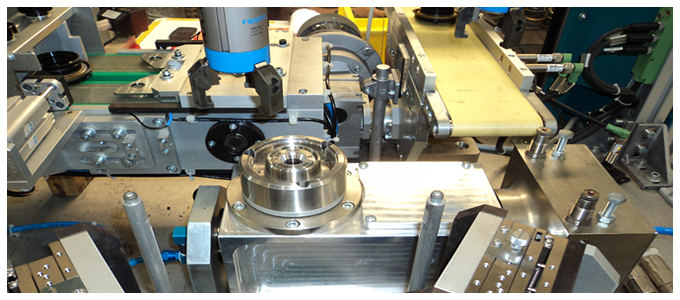

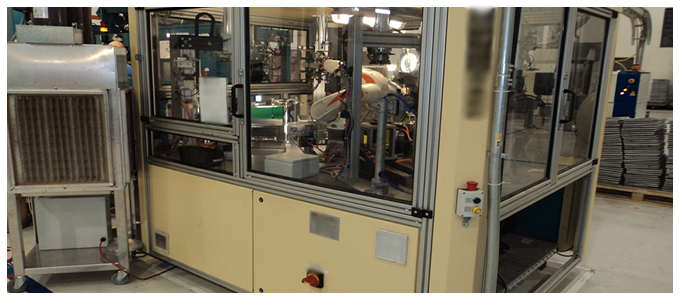

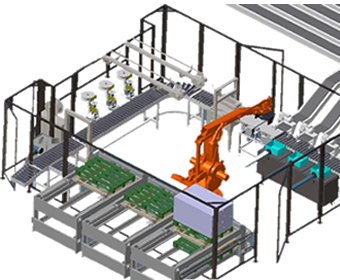

MCK executes special machines setting-up for production according to feasible projects developed by a team of MCK experts and designers, or project archetypes sent by our clients.

We provide services to all areas of the market, with great experience at the machine development, equipment and special automation devices in the most distinct areas of industry in general.

Our infrastructure convers a huge setting-up line, equipment integration and an expert team, with national and international qualification, professionals such as mechanics, technicians, designers and engineers.

We are able to offer appropriate solutions to attend our clients needs, taking into consideration aspects related to quality, productivity and economic viability

The original project requirements and specifications are fully respected, guaranteeing getting the defined results in the initial scope of the project.

Our specialization includes:

Robotic cells for material manipulation and several products, such as:

- Packaging and Palletizing

- Adhesive Application

- Welding Point, Arc Welding MIG / TIG

- Cutting, deburring and polishing operations

Special Machines and Equipment as:

- XYZ manipulators

- Machines for Load and Unload feeders

- Screwdriving systems

- Machines for functional tests, such as leaking, vibration and noise

- Data acquisition and Image inspection

- Current Conveyor

- Elevation Conveyor

- Treadmill Conveyor

- Roller Conveyor

- Continuous Conveyor

Modular Automation Including:

- Ergonomics work station

- Movement Carts

- Error proof devices, such as Poka-Yoke

- Manual setting-up devices and fixation devices

Safety According to PPRPS rules:

- Machine Enclosure

- Safety Commands

- Sensing and Safety monitoring

We manufacture Intra-logistics/ Movement Equipment:

- Driven rollers Conveyors

- Plastic Chains Conveyors

- Belts Conveyors

- Metal Chains Conveyors

- Free Rollers Conveyors

Special devices such as:

- Cardboard Feeders

- Pallets Magazines

- Tables for rollers and spheres transference

- Rotatory tables and pallets

- Inexpedient and product dividing tables

Wrapping-up machines such as:

Expert Machines to Rubber Areas

MCK has great experience and expertise at machines development, maintenance and retrofitting and focused equipment in rubber industry, such as:

- Equipment and dosing application for liquid rubber (LSR)

- Deburring Equipment (knife-machine)

- Electronic inspection by image equipment

- Automatic machines for spring mounting and grease application on seals

- Rubber Injectors reforms and retrofitting, vulcanization presses, cylinders, ban buries, preforms, etc.

Videos:

Rubber Injector Reform and Retrofitting REP V57

Reforms and Retrofitting

MCK Automação Industrial, integrated to its mission of providing innovative solutions to their clients, has a Unit of Business and Reforms & Retrofitting. Conscious of the economic reality the market has been through, MCK offers technological industrial machine and equipment updating solutions, as an economical attractive alternative in many cases.

With all the infrastructure of other business units at your disposal, the executed retrofitting and reform services, incorporate all the quality, technology and MCK Automação Industrial guarantees.

Among the range of reformed machines there are the vertical and horizontal lathes, cutters, rectifications, mandrels, machining center, presses, plastic and rubber injectors, special machines and others.

We have a complete professional team in the electrical and mechanical area, we don’t need outsourcing, enabling complete solutions, making MCK responsible for the work as a whole.

Our services include:

- Equipment complete setting-up

- Painting removal

- Rollers changes

- Damaged pieces machining

- Worn out or damaged pieces changes

- Chemical pieces treatment

- Belts Change

- Setting-up and start-up

- Electrical Installments Changes:

- Electrical panels and other command boards reform

- PLC and HMI Installment

- Modification in devices that represent chronical problems

- New devices Development

- Pneumatic Installment Reforms

- Engine and reducers maintenance

- Start-up and clients’ Follow-up

Did not find what you were looking for? Contact our technical team using the form below, and detail your needs to find the best solution for your company.

Other services

Learn about other services that MCK Automação can help your company with.

Assembly of Panels

MCK has panels in several industries and companies in the Brazilian market ...

Read MoreRobot Programming

MCK has a trained team with extensive knowledge in robot programming ...

Read More